Microplastic Issue and Unintentional Granule Loss

Pollution in the oceans and seas has reached a dangerous level. 80 percent of the pollution is caused by the mixing of terrestrial wastes into the seas. According to experts' estimates, approximately 142 million tonnes of waste is floating in the oceans. Every year, 10 million tonnes are added to this number.

The Marine Litter Issue

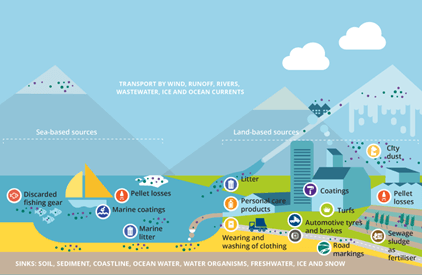

There is a growing concern about the presence of plastic in the environment. Plastic litter can contribute to global pollution by entering the soil, waterways and eventually the oceans. Much of the plastic pollution is caused by mismanaged waste. Interest in how microplastics contribute to this environmental problem is also growing. Marine scientists are reporting more frequently that birds, turtles and fish are ingesting a wide variety of plastic objects that can be harmful or even fatal to their health. The vast majority (80 per cent) of this waste is of terrestrial origin. This means that most of this waste is from wild landfill sites at the seaside, from improper waste management, potentially from carelessly discarded or unintentionally scattered products.

Plastics make our lives easier in many areas of our lives, but their place is never in our nature, environment, food or drinking water. To prevent this, all value chain actors, including producers, brand owners, consumers, recyclers and policy makers, need to work together. Plastics are crucial for our future. Our commitment as an industry is to ensure that plastics continue to provide the societal benefits needed without having a negative impact on the environment or health, and in particular to support the EU Green Deal targets.

Granule Shedding and Scattering Sources

Although high environmental, safety and quality management controls are applied in the plastics industry, unintentional loss of granules can occur at different stages along the value chain. While plastic granules are a raw material that should not be wasted, shedding and scattering can have serious environmental and social impacts.

The typical route of granules starts at a production facility. The granules are then sent either for storage or to plastic product manufacturers. There are four main types of packaging used in the packaging of granules: 25kg bags stacked on pallets, octabins (large cardboard boxes), bigbags, containers or silos.

Granules can be transported between different actors in the value chain, mostly by road, rail or sea. The finished product manufacturers then receive the granules in any of the packaging types described above. The granules are fed to extruders or injection moulding machines to be shaped into finished products. In some cases, granules are not sold by manufacturers directly to finished goods producers.

Trading companies and distributors may purchase large quantities of granules and store them in warehouses for resale in smaller quantities to finished product manufacturers. During the mechanical recycling of plastic products, most plastic waste is converted into similar raw materials such as granules or flakes. These materials follow the same cycle.

Spills occurring in confined spaces with no passageway to the environment should be contained. However, when spills occur outside of a confined area, the granules may enter drains and waterways before eventually entering the ocean.

It is therefore important that all workers handling granules are trained to react quickly and take appropriate measures to contain these spills. Granule loading and unloading operations pose the highest risk of loss at all stages of the value chain.